Much as we like to think the Mazda MX5 is a modern reinvention of traditional 60s roadsters many have now been on the road for decades. And, just like the old MGBs, Alfa Romeo Spiders and Triumph Spitfires that inspired the original design team, early MX5s are now classics in their own right.

And, just as with any classic car, Mazda owners will inevitably have to face dealing with rust at some point along the way. In this respect the MX5’s famous affordability is something of a double-edged sword, the fact proper rust repairs can often cost more than the car is worth consigning many otherwise decent cars to the great scrapheap in the sky.

Our case study here is a good example. A 1993 Eunos Roadster, it’s escaped the dreaded rot better than many, despite having spent over two-thirds of its 29-year existence on salty British roads. Rust can affect any of the first three generations of MX5, of course, but by nature of age and some well-known vulnerabilities Mk1s and Mk2s are most at risk. Sills and wheelarches are obvious spots but the more dangerous corrosion is that you can’t see, concealed deeper within the car’s structure. Mk2 front chassis rails are a good example, the double-skinned design meaning rust can spread from the inside out and, by the time it’s spotted, the opportunity for a repair making economic sense has passed.

Routine maintenance like keeping your wheelarches free of compacted dirt or cleaning out your hood drainage channels is good practice for any owner, this dedicated brush possibly the best money you could spend on your MX5! Those lucky enough to have somewhere warm and dry to store their Mazda during the wet winter months and able to avoid driving when the roads are covered in salt are also at an advantage.

But, short of never getting your MX5 out of the garage, you can’t totally avoid rust. And, at some point, you may have to address it, as happened with the car you see here.

The root of the problem here was a bodged rear-end repair carried out at some unknown point in the past. This came to light the last time it was repainted back in 2017, the crude seam where replacement rear quarters had been attached creating a rust trap that even scrupulous filling and preparation couldn’t entirely address. Sure enough blisters and bubbles started appearing and a major intervention was required.

Thankfully MX5 Parts has stock of original factory Mazda panels like the rear quarters required, these are worth the investment for the higher quality materials and better fit than cheaper pattern equivalents. As the previous repair proved, if you’re doing something like this it’s worth doing properly.

Given it’s hardly a DIY job for most people the parts are only half the story, and finding someone willing to fit them can be a struggle. Your typical insurance bodyshop probably won’t be interested but the MX5 community is full of clued-up folk able to recommend specialists like our chosen specialist, Sheffield-based Deepcar Autobodies. Having worked on this one previously Deepcar had the advantage of knowing what lurked under the surface, too.

Committing to a major bodywork overhaul of this kind isn’t to be taken lightly, on the basis once you start you’re going to have to see it through. And, often, the full scale of the job isn’t revealed until after the point of no return. While patch-up repairs for sills and wheelarches can be done relatively cheaply something this big demands time, and acceptance the final bill may be more than the car’s apparent value. This can be a tough call to make if you’re emotionally invested in your MX5 but, if you’re satisfied it’s worth the effort, financial realities can take a back seat.

Once at Deepcar it was a nervous wait for the verdict from main man Dave Burkinshaw. He’s seen it all in his time, and over the years has got used to breaking bad news to people. Indeed, one Mk1 had recently been dropped off for an apparently simple repair, only for the team to find the inner sills had basically turned to dust. The grimace on Dave’s face as he tells the story says it all, and many owners in a similar position would have taken the decision to walk away at that point. Thankfully this one didn’t, the work was done and another Mk1 was saved from the crusher.

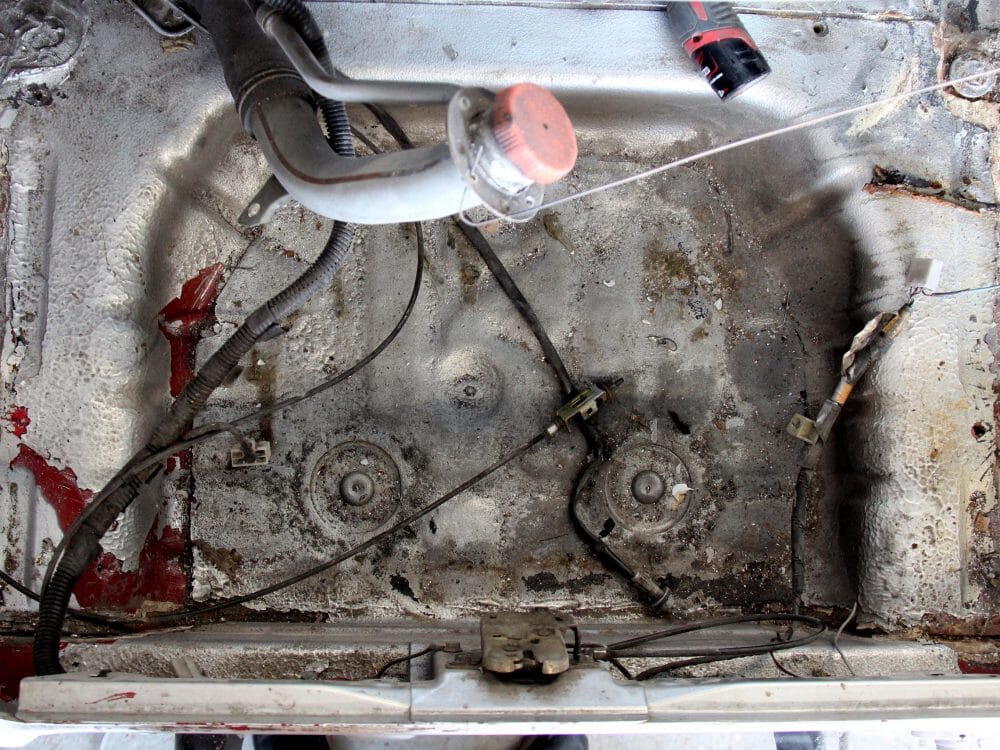

When it came to it for this car it’s both good and bad news. With the outer sills removed the inner sills and structure turn out to be in incredibly good nick. Round the back it’s not so good, with big holes in the rear valance, squidgy filler hiding a multitude of horrors where a new boot floor had been inexpertly grafted in and the boot surrounds crudely bodged to the extent they’d pretty much rusted away entirely.

Dave’s furrowed brow says it all but, by the next visit, the rusty bodywork has been cut away, fresh sections are welded in, primed and ready for painting and the new rear quarters from MX5 Parts are being prepared for fitting. With the bootlid refitted to check alignment these are then carefully teased into place, before being clamped in position ahead of firing up Deepcar’s freshly purchased spot welder. In practice it works almost like a giant stapler, operator Jack working his way along each seam to leave the characteristic ‘dimples’ for a proper factory look. As Dave explains, to get this authentic appearance before they’d have had to drill, weld and then fill each spot in a time-consuming process. The real time and effort has, of course, been in the prep to get this far but, by the time the panels are ready to go, the welding is actually a pretty fast process.

In what feels like the blink of an eye it’s looking like an MX5 again, the smooth curves of the rear quarters thankfully now free of the bubbles and blisters that lurked there before. Sorting out the panelwork is only half the job, though. And from here the car heads off into the Deepcar spray booth to get the paint looking as good as new. This is a whole different skillset of course, but one the guys here are well practised in. And by the next time we see it the car is looking as good as new.

Sparkling in the sunshine it’s hard to believe this is the same Mk1, the realities of the final bill a reminder of quite how much work has gone into making it look this good. Knowing the difference between a worthwhile investment and throwing good money after bad can be a tough decision sometimes, but if a car means more to you than numbers the commitment is as much emotional as it is financial.

If there was one lesson it’s that the bullet should probably have been bitten back when the dodgy repair was first discovered. Because while rust can be patched, repaired and sprayed over there’s no substitute for doing it properly. That can be a hard call when the temptations of fancy suspension, go-faster engine bits and any number of cool trim upgrades are on your shopping list too. And seemingly offer an easier win. But if a job’s worth doing it’s worth doing right.

Thankfully the bits you need to do the job are here on MX5 Parts, while specialists like Deepcar and others like them are there with the skill and patience to do the work to a standard you’ll appreciate every time your eyes land on the car.

A return that money can’t buy!

Featured Products:

Find body panel parts for your MX5

The story in videos…

Part One:

Part Two:

Part Three:

Leave your comment